لوله های پلاستیکی PE لوله های HDPE ماشین اکستروژن ماشین اکستروژن لوله های بزرگ PE خط تولید

کاربرد:

اینورتر دوگانه,تنش سیم تنظیم می شود طراحی اتوماتیک Nil-pulley، کارایی بالا صرفه جویی در انرژی از 20٪ تا 25٪ در مقایسه با ماشین سنتی استفاده از اجزای وارداتی برای حفظ کیفیت.

خط تولیدی پی ای لوله اکستروژن ما برای تولید لوله های HDPE با کیفیت بالا (پلی اتیلن با چگالی بالا) و PE (پلی اتیلن) در قطر های مختلف طراحی شده است،از جمله لوله های بزرگ برای صنایعاین خط اکستروژن پیشرفته دقت بالا، دوام و بهره وری انرژی را تضمین می کند، و آن را برای تولید لوله های مورد استفاده در آب رسانی، تخلیه،توزیع گاز، و سیستم های آبیاری.

تولید لوله PEمشخصات:

| مدل |

قطر لوله |

اکسترودر |

قدرت اکستروژر |

ظرفیت |

| LB-63 |

20 تا 63 |

SJ65/33 |

55AC |

150 |

| LB-110 |

20 تا 110 |

SJ65/33 |

55AC |

150 |

| LB-160 |

۷۵ تا ۱۶۰ |

SJ75/33 |

90AC |

280 |

| 250 پوند |

90 تا 250 |

SJ75/33 |

110DC |

350 |

| LB-315 |

110 تا 315 |

SJ90/33 |

160DC |

450 |

| LB-450 |

160 تا 450 |

SJ90/33 |

160DC |

450 |

| LB-630 |

۳۱۵ تا ۶۳۰ |

SJ120/33 |

280DC |

850 |

| LB-800 |

500 تا 800 |

SJ150/33 |

315DC |

1100 |

| LB-1200 |

۷۱۰ تا ۱۲۰۰ |

SJ150/34 |

400DC |

1350 |

فرایندهای فناوری

[تغذیه و خشک کردن] → [طراحی با اکستروزن] → [تشکیل قالب] → [برداری] → [کشش و برش] → [نشان دادن]

تغذیه و خشک کردن مواد

رزین PE با کیفیت بالا (HDPE / MDPE) در هپر بارگذاری می شود، سپس خشک می شود (اگر لازم باشد) برای حذف رطوبت برای اکستروژن بهینه.

اکستروژن و ذوب

این ماده به بشکه اکسترودر وارد می شود، جایی که یک پیچ چرخانگر آن را گرم می کند و آن را (160 °C ~ 220 °C) به حالت ذوب همگن تبدیل می کند.

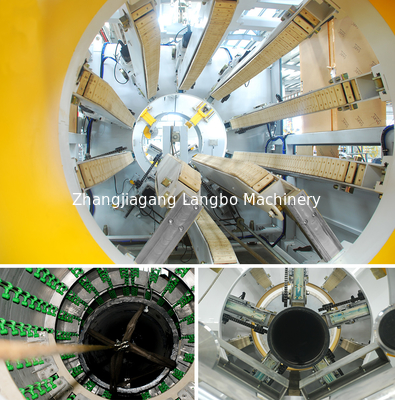

شکل گیری لوله

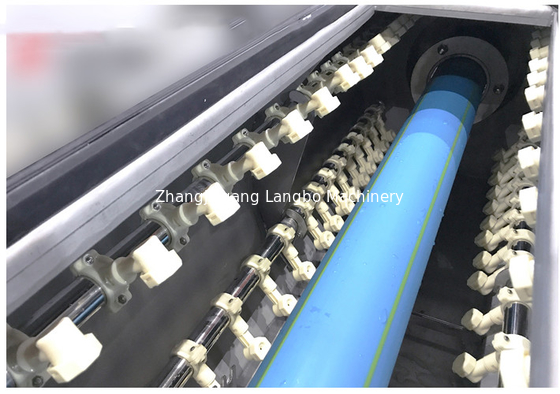

PE ذوب شده از طریق یک سر مرطوب شده فشار داده می شود و آن را به یک لوله مداوم با قطر دقیق و ضخامت دیواره شکل می دهد.

خنک سازی و اندازه گیری

لوله به یک مخزن کالیبراسیون خلاء برای خنک شدن سریع و ثبات ابعاد وارد می شود، اطمینان از اندازه و گردی ثابت.

حمل و برش

کشنده ها لوله را نگه می دارند و در حالی که آن را به طول های مشخص شده توسط یک اره خودکار برش می دهند، تنش را حفظ می کنند.

بازرسی و انبار

لوله ها قبل از انباشته شدن و بسته بندی، تحت بررسی کیفیت (ضغط، ضخامت، سطح) قرار می گیرند.

بسته بندی و نگهداری

لوله های آماده شده برای حمل و نقل برچسب گذاری، بسته بندی و ذخیره می شوند.

مزایا:

فشار سریع برای تولید کارآمد

سیستم کنترل PLC برای عملکرد دقیق

طراحی صرفه جویی در انرژی با عملکرد پایدار

مناسب برای مواد HDPE، PE100، PE80 و سایر مواد پلی اتیلن

قابل تنظیم برای قطرات مختلف لوله (از لوله های کوچک تا بزرگ)

خدمات قبل و بعد از فروش

• تجربه ی زیادی

• تمرکز مداوم بر بالاترین کیفیت

• یک سیستم کامل اندازه گیری خلاء دو لوله

• کنترل مستقل ساختار واحد دو دستگاه کشیدن لوله و دستگاه برش همزمان؛

• تنظیم طول اختیاری و پیکربندی دقیق.

• یک تیم با انگیزه بالا

• تکنولوژی فرآوری پیشرفته

• راه حل های سفارشی

کارخانه ما

نمایشگاه ما

حمل و نقل کالا

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!

امتیاز کلی

بررسی اجمالی امتیاز

توزیع تمام رتبهبندیها به شرح زیر است.همهٔ بازبینیها