Single Screw Extruder PE HDPE Pipe Making Machine

APPLICATION:

It is mainly composed of Main extruder, sub-extruder, die-head, vacuum tank, haul off, and winding machine auto cutting machine and auto stacker

Usage: HDPE pipe making machine can produce one layer/two layers HDPE pipes, good performance and low noise.

PE PIPE PRODUCTION SPECIFICATIONS:

| Model |

Pipe diameter |

Extruder |

Extruder power |

Capacity |

| LB-63 |

20-63 |

SJ65/33 |

55AC |

150 |

| LB-110 |

20-110 |

SJ65/33 |

55AC |

150 |

| LB-160 |

75-160 |

SJ75/33 |

90AC |

280 |

| LB-250 |

90-250 |

SJ75/33 |

110DC |

350 |

| LB-315 |

110-315 |

SJ90/33 |

160DC |

450 |

| LB-450 |

160-450 |

SJ90/33 |

160DC |

450 |

| LB-630 |

315-630 |

SJ120/33 |

280DC |

850 |

| LB-800 |

500-800 |

SJ150/33 |

315DC |

1100 |

| LB-1200 |

710-1200 |

SJ150/34 |

400DC |

1350 |

Details description

PE pipe production line comes with all the necessary machinery you need to start manufacturing high quality PE pipe. From the single screw extruders comprised of quality components to a high speed servo powered puller machines we offer you everything you need to become a successful pipe manufacturer.

Material Feeding

PE/HDPE raw material is fed into the hopper of the single-screw extruder.

Melting & Extrusion

The material is heated and melted inside the extruder barrel, then pushed through a die head to form a continuous pipe shape.

Vacuum Calibration (Sizing)

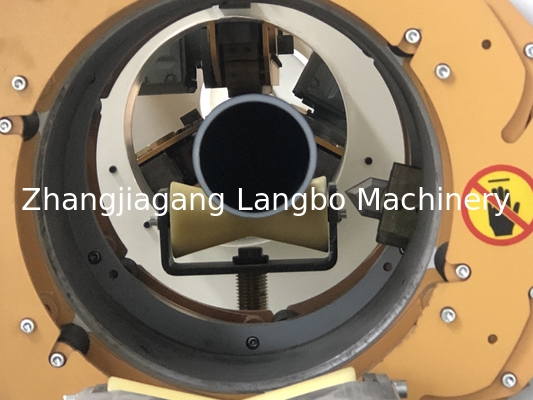

The molten pipe passes through a vacuum calibration tank to ensure precise diameter and roundness.

Cooling

The pipe enters a cooling water tank to solidify and maintain its shape.

Haul-Off (Pulling)

An automatic haul-off unit pulls the pipe at a controlled speed to maintain consistency.

Cutting

A cutting device trims the pipe to the desired length.

Stacking & Packaging

The finished pipes are collected, inspected, and packaged for delivery.

Advantages

Single-Screw extruder with high torque and stable output

Advanced vacuum sizing system for precise diameter control

Efficient cooling system for uniform pipe solidification

Automatic haul-off & cutting unit for consistent pipe length

PLC control system for easy operation and monitoring

Durable construction for long-term reliability

PRE- AND AFTER-SALE SERVICES

• A great wealth of experience,

• A consistent focus on the highest quality

• A complete twin pipe vacuum sizing system;

• Controlled independently unitary structure twin pipe hauling mechanism and synchronous cutting device;

• Optional length set and accurate adaption stacker.

• A highly motivated team

• Sophisticated process technology

• Customized solutions

Our factroy

Our Exhibition

Our Goods Shipping

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!